2021-08-04

Design multiple drives to be more service-friendly

RINGSPANN is expanding its FXR freewheel series with a new variant with reverse rotation function

The main field of application for the integrated freewheels of the FXR family from RINGSPANN are the multiple drives of conveying, separating and crushing systems in bulk materials and mining technology. In order to give designers in these industries even more scope for the realisation of safe and maintenance-friendly drive solutions in the future, the German freewheel specialist has now expanded this globally proven series with an innovative variant called FXRB. In addition to a torque limiter and a controllable release device, it excels with a new reverse running function. This considerably reduces the costs required for maintenance and clearance work.

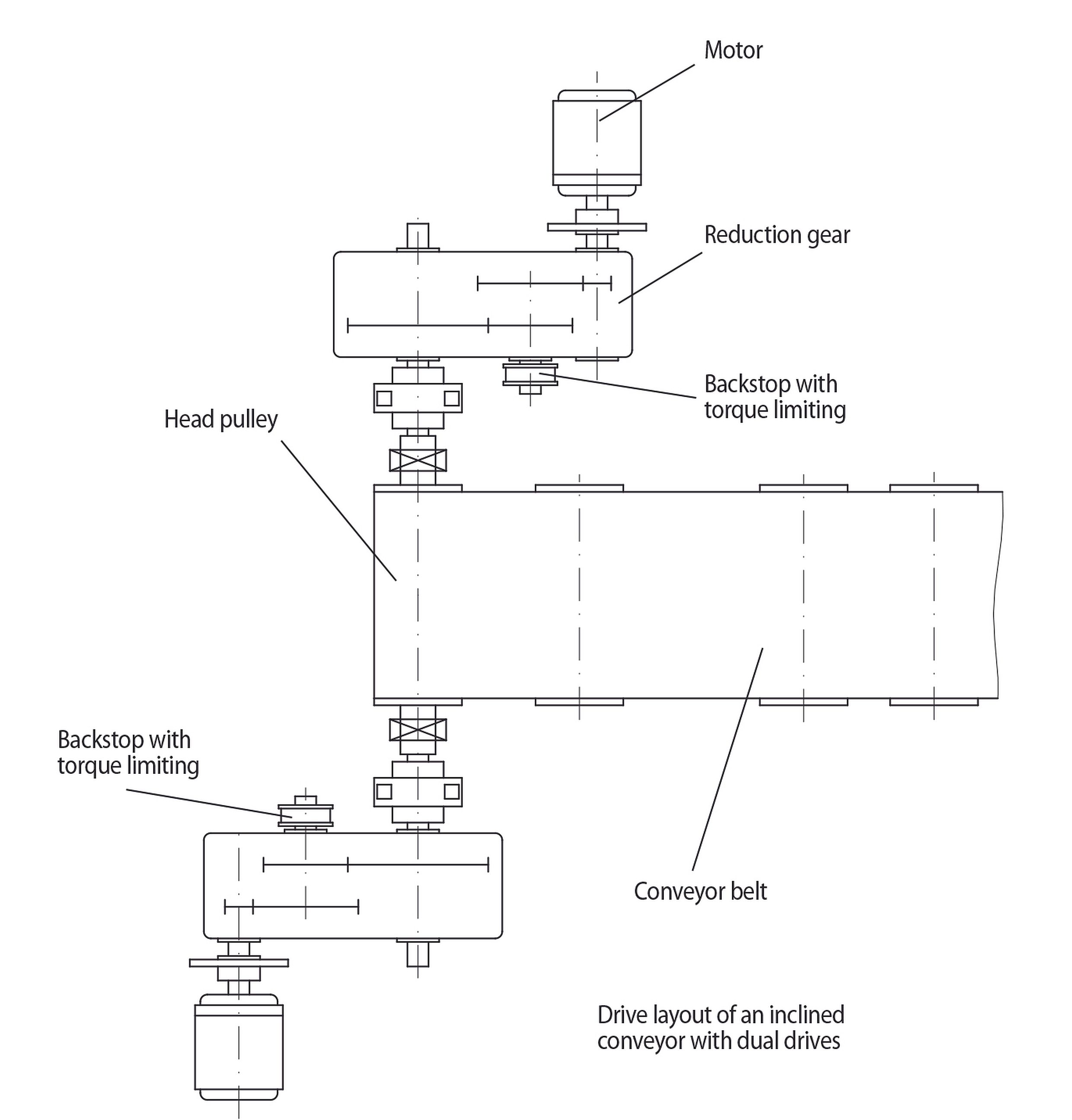

Bad Homburg, August 2021. – RINGSPANN’s FXR freewheels are primarily used as backstops in the types of multiple drives that are typical for continuous conveyors, crushing mills, bucket elevators or dryer drums and screw pumps in bulk material, hydro, recycling and mining technology. In addition to the sprag lift-off X (see info box), the special quality features of these freewheels include torque limitation and - depending on the design - an integrated release device that can be controlled with great precision. Thomas Heubach, in charge of the freewheel division at RINGSPANN, explains: "Our FXR backstops with a release device are among other things found in belt conveyors where a precisely controllable release of tension on the belt or the entire system and a limited reverse rotation of the belt drive must be possible at any time - for example, when guide rollers jam." However, it sometimes turns out in practice that a partial reverse movement of a conveyor system is not enough to completely eliminate faults and quickly resume operation in some situations. To overcome this limitation, Thomas Heubach’s team has developed a new FXR variant that not only allows controlled release under full load, but also unlimited idling in reverse operation. With this new backstop - available immediately under the designation FXRB - RINGSPANN opens up additional scope for design engineers to realise maintenance-optimised drive systems where the costs for maintenance, repair and clearance work can be significantly reduced. Manufacturers of conveying and shredding systems thus gain an important advantage in international competition.

Staggered distribution of harmful forces

Including the new variant, RINGSPANN now offers a total of five designs of integrated freewheels for slip torques up to 107,000 Nm in the FXR series, which can be used as backstops in multiple drives. As indicated, they all have a torque limiter. This allows the problem of an uneven distribution of the return torque in multiple drives - for example of continuous conveyors - to be solved very elegantly. Thomas Heubach explains: "Without torque limitation, the designer would for safety reasons have to design each backstop on each gearbox for the entire return torque of the conveyor system, as this would primarily act on only one backstop in the event of a system stop due to the different clearances and elasticities in the drives involved. The FXRs don’t even let this happen, because their torque limiters slip briefly when the set torque is exceeded until the other backstops successively engage." This means the entire return torque of the system is distributed among the individual backstops of the gearboxes. In addition, the dynamic torque peaks are reduced during the locking process, so that all drive elements are protected against their damaging effect. As a result, when using RINGSPANN’s FXR backstops, the gearboxes of multiple drive systems can be dimensioned smaller and more compact, which opens up further optimisation potential for the system manufacturer.

Innovative reverse running function

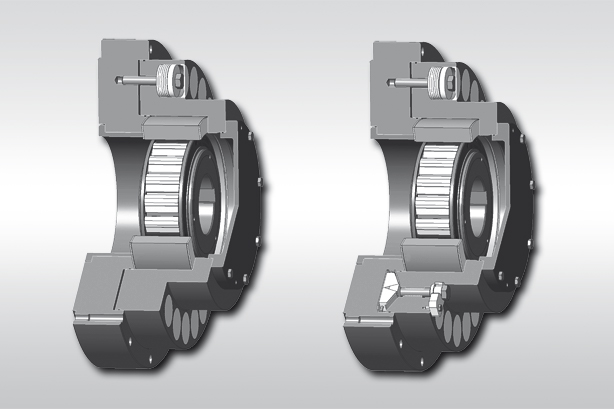

The individual versions of the FXR series from RINGSPANN are each offered as standard in ten sizes with bores from 65 to 240 mm and are designed for front screw mounting on drive shafts. In addition to the common features of sprag lift-off X and torque limitation, they are available in variants with (FXRU) and without (FXRW)a release device, as well as in the new FXRB variant with a free reverse running function. In the latest generation, all FXRs have high-performance carbon friction pads. Compared to the organic friction linings used in the past, they enable significant torque increases and allow the outer diameters of the freewheels to be made smaller, which is why the FXRs are so compact. "For older applications, however, we still offer the old versions with the organic friction linings," says Thomas Heubach.

If you ask the head of RINGSPANN’s freewheel division about the design refinements of the innovative reverse function of the new FXRB freewheels, he is understandably reserved. He does at least reveal that plain bearings – seen with other designs on the market - do not play a role here: "Plain bearings only enable short-term reverse movements of the system. We use a different bearing basis for the free reverse function of our FXBR," says Thomas Heubach. It is also worth mentioning that the release device is purely mechanical as standard; however, a hydraulic release is offered as an option.

Global market leadership

In addition to the catalogue selection of FXR freewheels available at short notice, RINGSPANN also produces special designs on customer request - for example for unusual bore dimensions or special flanges. Depending on the requirements and quantities, the RINGSPANN Group can harness the capacities of eight production plants worldwide. "We view both the extensive international distribution of our FXR series and the new FXRB variant as proof of our market leadership in the global freewheel market and our positioning as a one-stop supplier for high-quality clutches and brakes in industrial drive technology," emphasises Thomas Heubach. ar

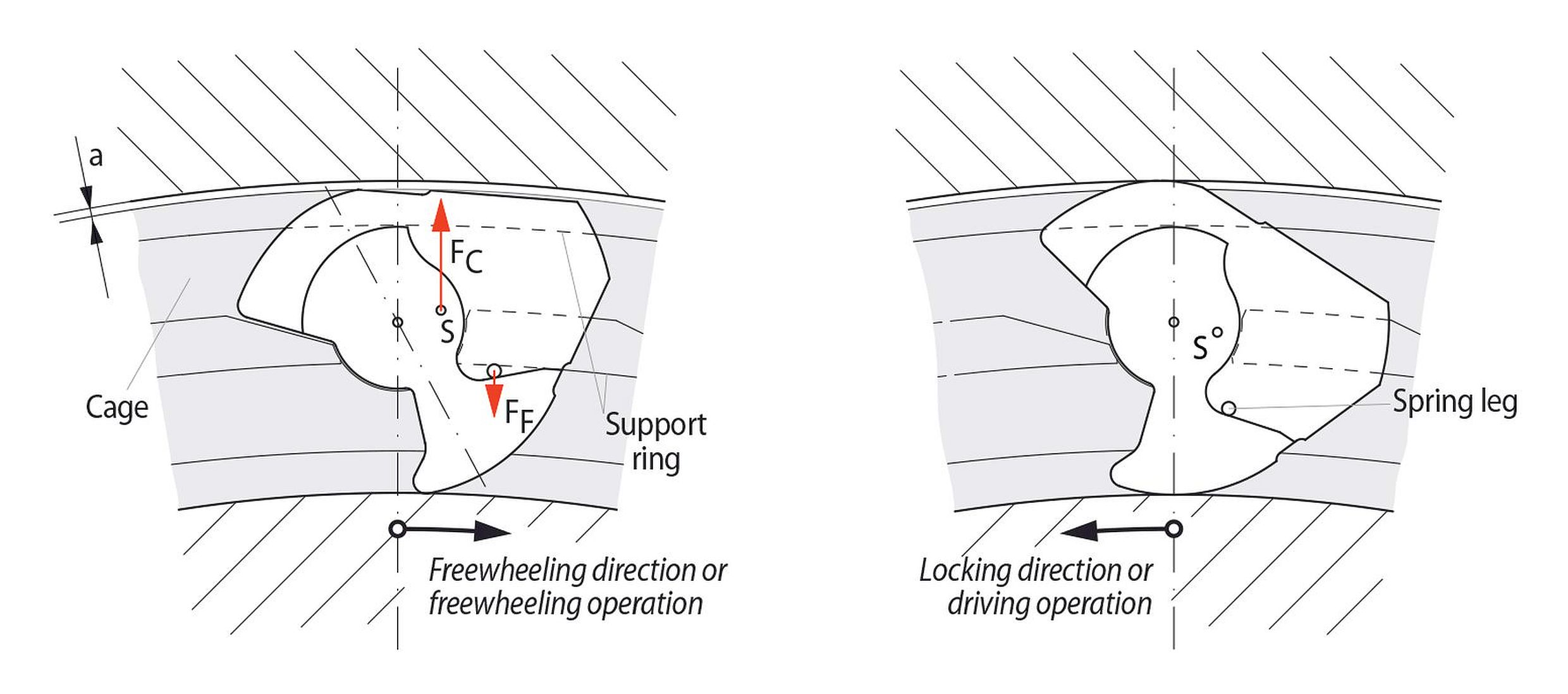

The sprag lift-off X

The sprag lift-off X is used in RINGSPANN backstops and overrunning clutches when in freewheeling operation the inner ring rotates at high speed and when in overrunning function the driving operation is carried out at low speed. In freewheeling operation, the centrifugal force causes the sprags, manufactured in an X-like form, to lift off from the outer track. The freewheel then works wear-free and with an unlimited service life. The sprags, which are supported in a cage connected with the inner ring, rotate with the inner ring. The centrifugal force turns the sprag counter-clockwise and rests against the support rim of the cage, creating a gap between the sprag and the outer track; the freewheel therefore operates without contact. If the inner ring speed now decreases to such an extent that the effect of the centrifugal force on the sprag is less than that of the spring force, the sprag against rests on the outer ring and "switches" the freewheel to locked condition. Please note: If used as an overrunning clutch, the driving speed must not exceed 40 percent of the lift-off speed.