2023-12-13

Innovation for the first and second clamping step

New precision clamping fixture from RINGSPANN simplifies turning and milling processes

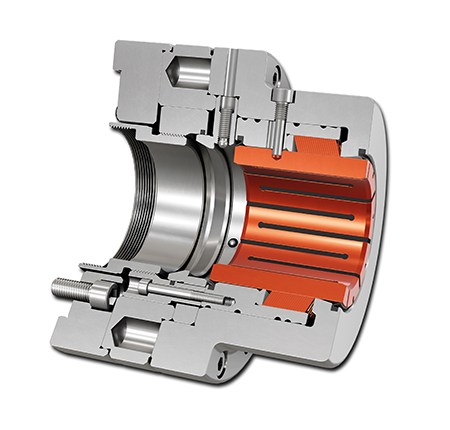

More flexibility in machining production and significantly reduced setup times – these are the premises under which RINGSPANN presents the new HSFS 110 clamping sleeve chuck. This innovative precision clamping system offers numerous advantages, especially for users of turning/milling machines with main and counter spindles and machine tools with bar loaders. Since it does not require pull-back action, it is equally suitable for machining bar stock and material sections in the first or workpieces from the second clamping step.

Bad Homburg, December 2023. "The aspects of increasing flexibility and reducing setup times were the focus of our considerations for a new clamping system for use in machining production," says Christoph Schulz, Product Manager Clamping Fixtures at RINGSPANN. As a concrete result of the development work, the company is now presenting the HSFS 110 clamping sleeve chuck, which is of interests both machine builders and users. The new precision clamping system from RINGSPANN offers considerable efficiency advantages, especially when using machine tools with fully automatic barfeeders and turning-milling machines with two spindles. These include, among other things, the fact that it works without pull-back action – a technical prerequisite for use with bar loaders – and that its design allows for a very simple and quick replacement of the clamping sleeves. With clamping diameter range from 22 mm to 80 mm, the new HSFS 110 from RINGSPANN is an extremely versatile clamping fixture for many different tasks. It also provides the user with additional flexibility, not least because it allows the clamping diameter to be changed by up to 1.5 mm. "Our HSFS 110 allows for large workpiece tolerances and insertion clearances. It is therefore also suitable for automated loading," explains Christoph Schulz.

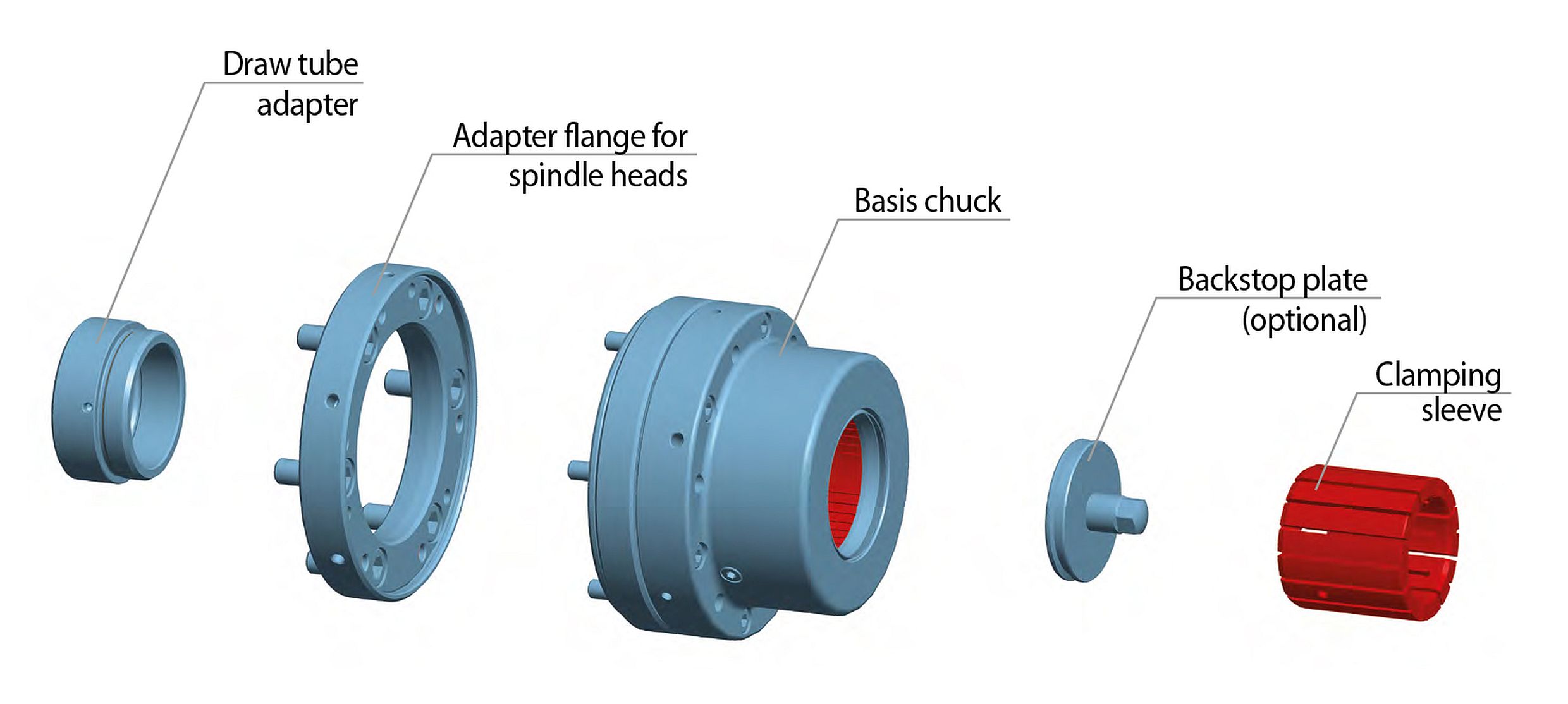

Clamping sleeve as an interchangeable part

The new HSFS 110 clamping sleeve chuck from RINGSPANN is a purely mechanical clamping system and consists of a base chuck, a clamping sleeve as, well as a draw tube adapter and an adapter flange. While the adapter flange connects the machine spindle to the base chuck, the draw tube adapter transfers the actuating force from the clamping force device of the machine spindle into the base chuck. The clamping sleeve is an interchangeable part that can be replaced easily, quickly and as required without special tools. "In addition, the use of individually designed stop plates makes it possible to load and process workpieces axially positioned from the front. For this reason, the HSFS 110 can also be used for material sections in the first clamping step without any problems," explains Christoph Schulz.

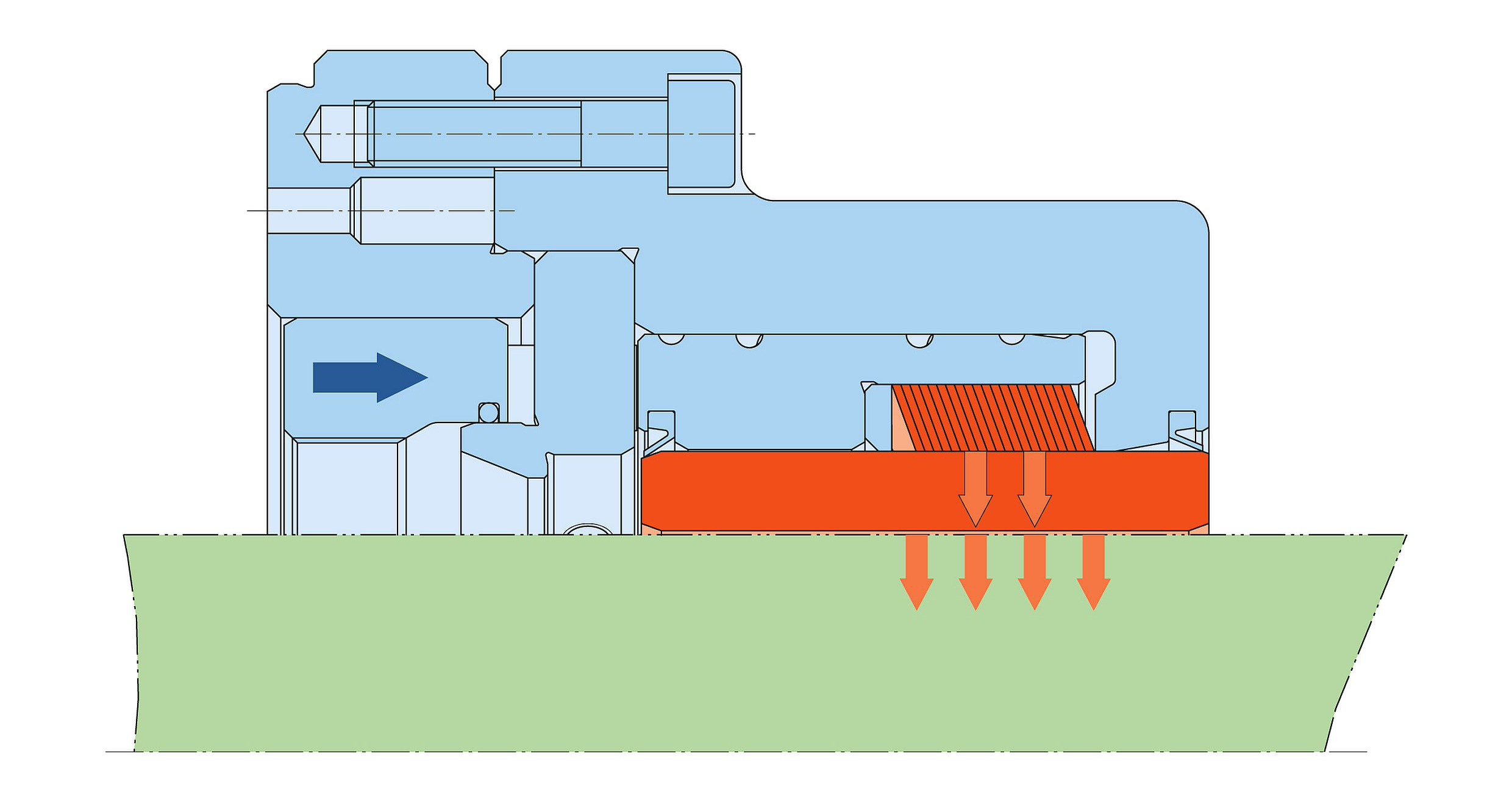

The clamping principle of the new HSFS 110 from RINGSPANN can be described in a few words: clamping discs with preload are located in an axially movable mount. If the holder is then shifted axially during clamping, the clamping discs straighten up and the clamping sleeve firmly clamps the workpiece. In this process, the workpiece is centered, and the axial actuating force is translated into a radial clamping force up to ten times greater. The maximum torque achievable depends on the diameter of the bar material to be machined. Two limits provide orientation: rods with diameters of 80 mm are clamped at up to 470 Nm, while the maximum torque for rods with diameters of 22 mm is 85 Nm. "At the same time, the chuck of the HSFS 110 ensures uniform, safe and precise 360° clamping around the workpiece at all times," emphasizes Christoph Schulz. In numerous tests, the HSFS was able to attest to an extremely smooth running.

Sleeves, flanges and plates for all occasions

The specific size of the HSFS 110 clamping sleeve is defined by the rod`s diameters or the sections and workpieces that are to be machined. As standard, RINGSPANN offers a selection of 28 different clamping sleeves for as many diameters of rods (according to EN 10278) or cylindrical workpieces. The clamping sleeve can be changed in just a few simple steps, no special tools are required – an Allen key is sufficient!

The adapter flanges for connection to the spindle heads of various machine tools are always designed by RINGSPANN according to customer requirements. According to Christoph Schulz, "short flanges for short-cone connections are also part of the range". The draw tube adapters are also adapted to the specific case – here the spindle geometry and the design of the draw tube of the power clamping device serve as decisive specifications. As already indicated, the stop plates can be individually designed for front loading with material sections or workpieces.

The new HSFS 110 clamping sleeve chuck, RINGSPANN offers manufacturers and users of machine tools a modern precision clamping system, which many turning and milling processes of the first and second clamping step can be carried out extremely flexibly and efficiently. Thanks to its high adaptability and easy handling, it is also one of those clamping systems that can give the machining of workpieces a noticeable economic efficiency impulse. ms